Building a Custom Two Piece Wheel

How it's done

Here is a catalog of pictures showing how a custom two piece wheel is built. American Racing is a leader in the custom built-to-order two piece wheel market. With so many wheel size options available with different lug patterns and backspacing it only makes sense to build them to order.

Barrels With an order placed, the components for the wheel are gathered together and put into the wheel assembly area with the work order.

Centers Once the machined center section is complete the proper barrel is selected, we use 6061 forged aluminum barrels from Indiana.

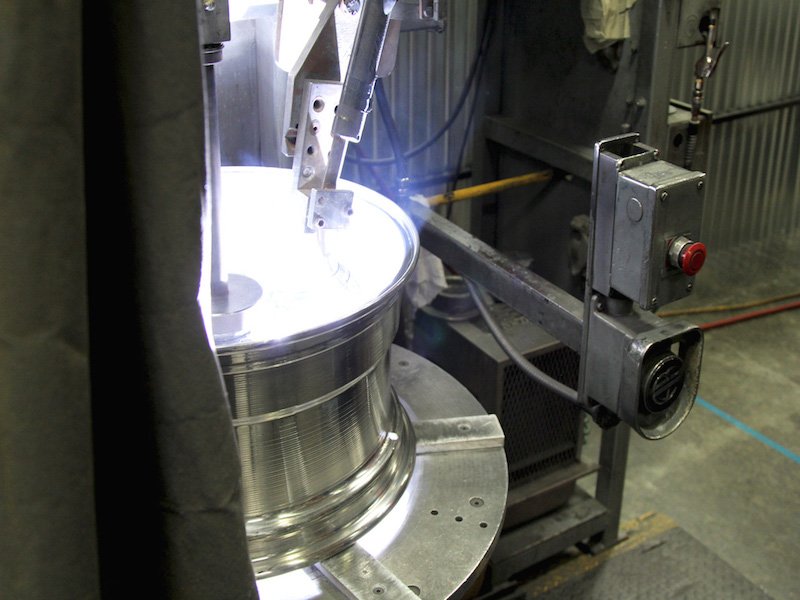

Prep the Barrel After the valve stem punch the barrel is then heated to expand it making it easier to slip over the center section.

Shim for Backspace While the barrel is being heated the center section is placed on a jig where shims are used to achieve the proper backspacing for each wheel.